Wire Cable Trays: Code Compliance and Modification

By: CableOrganizer®

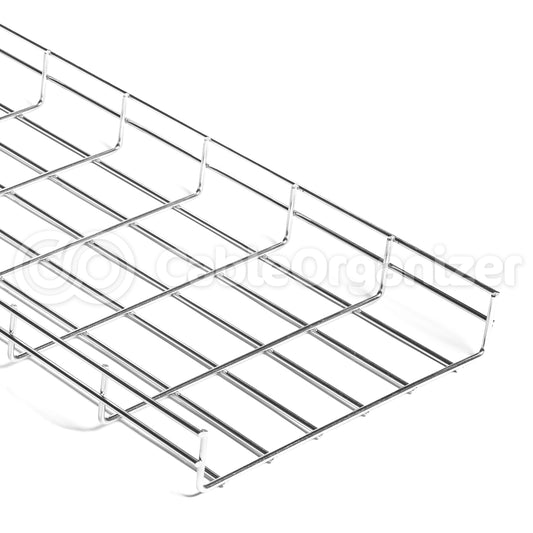

When it comes to basket-style cable trays, you'd think it would be a simple and a straightforward matter to get them to turn in different directions. They're made of heavy-gauge steel wire, so you should be able to just pull out your cable tray cutter, snip out a few strategic rungs and form your bend, right? Wrong — not if you want your installation to meet National Electrical Code (NEC) and UL Solutions requirements (and believe us, you do).

Failed inspections not only equate to downtime for the facilities unlucky enough to be saddled with them but can also mean delayed payment for the installation contractor. Any way you slice it, someone is going to lose out. If you have an upcoming cable tray installation, be sure to take our simple code-compliance advice — set your project up for a passing grade from the get-go.

HOW COMPLIANT CABLE TRAYS GO BAD

It doesn't matter if your cable tray system was UL classified or NEC compliant when it left the factory — as soon as it is field modified, it automatically loses its code-compliant status. Why the sudden change? For starters, UL does not stand behind field modified parts, because they have no way of verifying or guaranteeing their safety post-modification. And because electrical inspectors who inspect and give your installation the final thumbs-up rely on UL to cover liability for the installed products, any modification violating UL regulations can result in an automatic failure during inspection.

Further, NEC article 392.5(E) specifies that proper fittings must be used whenever cable trays change direction or elevation. Just as with UL's requirements, this means you can't change the path of a cable tray by removing parts (like rungs) and bending. You need to instead add on fittings that not only allow for the directional change, but also maintain the cable tray's structural integrity and grounding path.

KEEPING YOUR CABLE TRAY INSTALLATION ON THE RIGHT PATH

Sound complicated? It isn't, if you're using products that fulfill both structural and grounding requirements. WireRun® Cobia® Galvanized Mesh Cable Trays are one option. Choose from straight sections plus couplers, corner strengthening bars, elevation change support bars, fast fix splices, cable sectioners, waterfall cable drops, and other components to customize the path for your wiring. The WireRun® Cobia® Powder Coated Cable Trays are lightweight options that are smooth coated to prevent both cable jackets from nicking and zinc whiskers. In addition to the straight sections, there are L Junctions and T Junctions to make 90° turns. Fastlock keeps bends connected at cut points.

The Snake Tray® system is made of flexible and hand-bendable steel that can be turned in nearly any direction without cutting. Many of the Snake Tray® items can be mounted along walls or ceilings, bending in roller coaster style, while being attached to walls without brackets to support cables of all types, including fiber optic ones.

The Snake Tray® Snake Canyon® Cable Tray is a drop-in style that is designed for raised access flooring. There is additionally the Raised Floor Cable Tray System for low to medium voltage cables, which can be set as close as two inches from its underside for easy maintenance.

A FEW HELPFUL STANDARDS BASICS YOU'LL NEED TO KNOW

Under NEC Article 392, metallic cable trays are required to:

- Be strong and rigid — They need to be able to support all the wiring they're going to contain.

- Have smooth edges — Burrs, sharp edges, and other projections can damage cable jackets and insulation.

- Be protected from corrosion — Hot-dip galvanization or powder coating is a must.

- Have side rails — Overall tray structure needs to be solid and able to contain cables.

- Have fittings — Changes in direction and elevation need to be accomplished with the proper fittings and hardware.